⚙️ Advanced Manufacturing

At Helios Solar, we take pride in our team of highly skilled engineers and dedicated staff who drive innovation and quality across every stage of production.

Since our inception in 2016, our state-of-the-art manufacturing facility in Bengaluru, India, has been delivering premium solar modules trusted by clients across sectors.

Our semi-automated production lines, equipped with cutting-edge machinery sourced from Europe and Asia, ensure consistent reliability and precision in every module we produce.

Thanks to streamlined processes and harmonized operations, we are capable of manufacturing high volumes of top-quality solar modules at exceptional speed, without compromising on quality. Our dust-proof, contamination-controlled environment further enhances the integrity and performance of our products.

At Helios Solar, we don’t just manufacture solar modules we engineer solutions built for performance, durability, and sustainability.

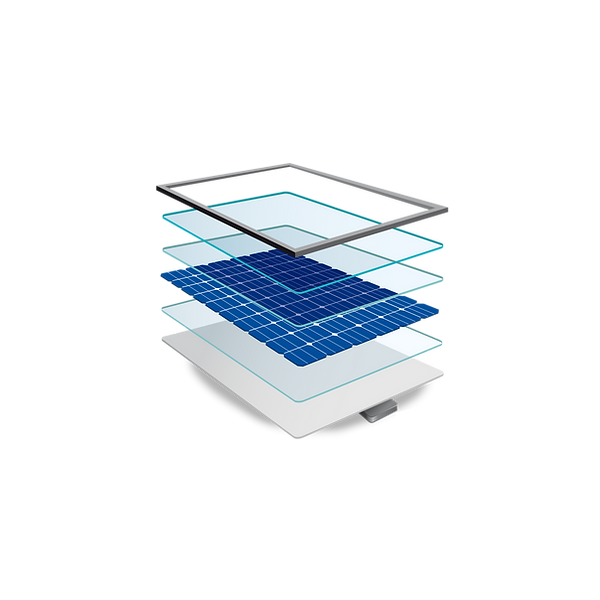

Al Frame - Deep anodized Aluminium frames which are resistant to corrosion and abrasion which enables protection from salt and mist corrosion

Glass - High transmission low iron,

tempered & PV grade glass

EVA Sheet - Fast cure, UV

stable EVA photovoltaic

encapsulant

Solar Cells - Cells employed

are of excellent low light and

optimal thermal co-efficient

performance

EVA Sheet - Fast cure, UV

stable EVA photovoltaic

encapsulant

Back Sheet – Tedlar based

back sheet for proven longer

life of modules

Junction Box – Fully potted IP67

JunctionBox with Schottkybypass

diodes having excellent thermal

stability

Making of Our Solar Modules

Our Solar Panel Manufacturing Process

We follow a meticulous and quality driven manufacturing process to ensure every solar module delivers exceptional performance and long-term reliability.

2.Lamination, Hot Press & Cool Down

This is the core stage of the manufacturing process where all the essential elements of the panel are layered and laminated to form the heart of the PV module.

-

Using our next-generation SIEMENS Module Laminator, the layers are hot pressed at 155°C for 10 minutes, bonding them into a single unit.

-

The laminated structure is then cooled to stabilize the panel.

This process ensures structural integrity, durability, and resistance to environmental factors key for long-lasting performance.

3.Taping & Framing

Once lamination is complete:

-

The panel edges are trimmed and sealed with industrial-grade adhesive tape.

-

A corrosion-resistant aluminum frame is then installed to provide mechanical strength and protection, enabling the panel to withstand harsh weather conditions and mechanical stress.

1.Tabbing & Stringing

In this initial step, solar cells are connected using a precision-controlled soldering process. The temperature is carefully maintained to prevent cell damage or micro-cracking, while ensuring strong, lasting connections. This step is accurately time-bound and quality-monitored, laying the foundation for the panel’s durability and electrical efficiency.

4.Junction Box, Testing & Packaging

-

A junction box is affixed to the rear side of the panel, allowing for safe and reliable electrical connections.

-

Each module undergoes rigorous testing under standard testing conditions (STC), including a “flash test” to ensure its power output meets rated specifications.

-

Only panels that meet our strict quality standards proceed to final packaging and are shipped to our customers with full confidence.

Call Us

+91-9902627799 / 9632959789

Visit Us

Ground, 14, 3rd Cross, Nethaji Nagara, Chokkasandra, Bengaluru Urban, Karnataka, 560057

Follow Us on Social Media

Stay connected and get the latest updates: